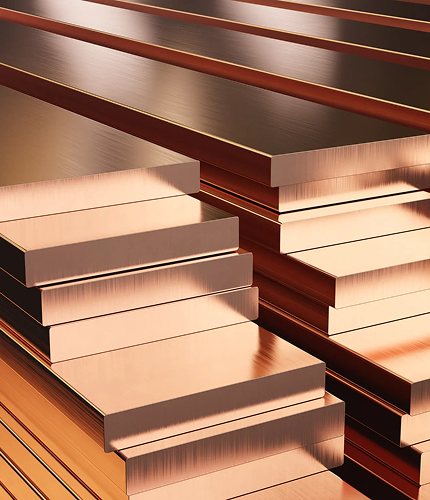

OFC & ETP Grade High Precision & Plated

| SPECIFICATION | ||||

|---|---|---|---|---|

|

|

OFC Grade | ETP Grade | ||

|

|

C10200 - Cu 99.95% Oxygen < 10 ppm Cond – 100% Min. in Annealed and 98.3% in Half Hard & Full Hard as per (I.A.C.S.) |

C11000 - Cu 99.90% Oxygen < 400 ppm Cond – 99.25% Min. in Annealed and 97% in Half Hard & Full Hard as per (I.A.C.S.) |

||

|

|

Thickness | Width | Thickness | Width |

|

1 – 25 MM 5 – 25 MM 6 – 20 MM 8 – 15 MM 10 – 12 MM |

10 – 80 MM 10 – 100 MM 10 – 160 MM 10 – 200 MM 10 – 250 MM |

1 – 25 MM 5 – 25 MM 6 – 20 MM 8 – 15 MM 10 – 12 MM |

10 – 80 MM 10 – 100 MM 10 – 160 MM 10 – 200 MM 10 – 250 MM |

|

|

|

Cross section area 8 to 3200 Sq. mm Maximum | |||

|

|

SI 1897, IS 191 & IS 613 and BS EN 13610, JSI 3140 | |||

|

|

Full Round (FR)

Full Round (FR)

Slightly Round Edge (SE)

Slightly Round Edge (SE)

Square Bar (SQ)

Square Bar (SQ)

|

|||

|

|

1000 mm to 4500 mm 30 – 80 Kgs coils |

|||

|

|

Annealed, Half Hard & Full Hard as per customer requirement | |||

|

|

Tin, Silver, Nickel plating as per customer requirement | |||

For making finished components used in Electrical Panels, Switchgears, GIS, Generator, Motors, Transformers, Traction Motor, alternator etc.

Heavy Industries

Power Generation (thermal, hydro, nuclear, solar, wind)

Power Transmission & Tele-communication

Electric Vehicle & Battery Manufacturer

Aerospace & Defense

Pharmaceutical & Medical Devices

Construction / Infrastructure